Back to Socket Head Shoulder Bolts Menu

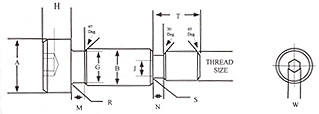

DIN SB 912

THREADS: ISO 262

(coarse series only)

|

|

Dimensions |

Application Data |

|||||||||||||||

|

Nom. |

|

|

A |

F |

G |

H |

J |

M |

N |

R |

S |

T |

W |

Recommended |

|

|

|

Size (B) |

Thread |

|

|

|

|

|

|

|

|

|

|

|

|

Seating Torque |

Tap Drill |

|

|

mm |

Size |

Pitch |

Max. |

Min. |

Max. |

Max. |

Min. |

Max. |

Max. |

Max. |

Max. |

Max. |

Nom. |

N - m |

in.-lbs. |

Size |

|

6.00 |

M5 |

0.8 |

10.00 |

2.4 |

5.62 |

4.50 |

3.70 |

1.85 |

2.40 |

0.35 |

0.66 |

9.75 |

3 |

7 |

60 |

4.2 |

|

8.00 |

M6 |

1.0 |

13.00 |

3.3 |

7.62 |

5.50 |

4.43 |

1.85 |

2.60 |

0.40 |

0.69 |

11.25 |

4 |

12 |

105 |

5.0 |

|

10.00 |

M8 |

1.25 |

16.00 |

4.1 |

9.62 |

7.00 |

6.06 |

1.85 |

2.80 |

0.50 |

0.80 |

13.25 |

5 |

29 |

255 |

6.75 |

|

12.00 |

M10 |

1.5 |

18.00 |

4.9 |

11.62 |

8.00 |

7.72 |

1.85 |

3.00 |

0.65 |

0.93 |

16.25 |

6 |

57 |

500 |

8.5 |

|

16.00 |

M12 |

1.75 |

24.00 |

6.2 |

15.62 |

10.00 |

9.38 |

1.85 |

4.00 |

0.80 |

1.03 |

18.25 |

8 |

100 |

885 |

10.25 |

|

20.00 |

M16 |

2.0 |

30.00 |

8.8 |

19.62 |

14.00 |

13.00 |

2.65 |

4.80 |

1.00 |

1.30 |

22.25 |

10 |

240 |

2125 |

14 |

|

24.00 |

M20 |

2.5 |

36.00 |

10.0 |

23.62 |

16.00 |

16.35 |

2.65 |

5.60 |

1.20 |

1.46 |

27.25 |

12 |

470 |

4160 |

17.5 |